Product Categories

Contact detail

- Mobile Phone:+86 13662603519

- Tel:+86 755-23063852 13662603519

- Email:master@jh-com.com

Chat Now:

Waterproof Design

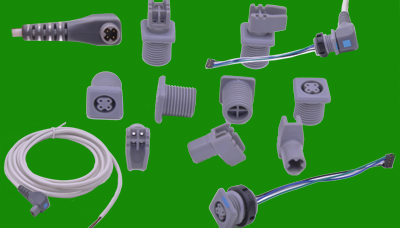

Waterproof industrial connectors, cable, metal, plastic, electronic products Assembly Electronic sensor waterproof box wired waterproof box,Optional specification M12 M5 M16 M8 waterproof connector structure design components research and development design, 2 d, 3 d engineering drawings services, product structure design services, high precision 3 d version of the service, prototype manufacturing and other related supporting services, assist clients to achieve interconnection solutions for new products, plastic shell products, outdoor products, such as encapsulation waterproof design, the corresponding mold design and mold manufacturing, parts of customized samples and mass production.

For more product information, please click http://connectors-cable.com

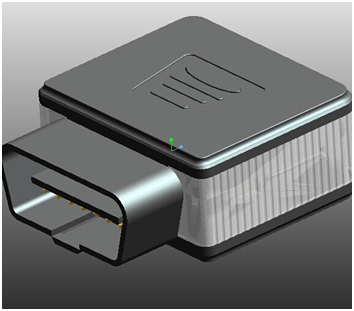

Custom Connector Developing

Then we can relieve you of these troubles.We can provide rapid research and development, design, sample production and testing, and quickly submit the samples to you for confirmation, so as to quickly enter the mass production, and at the same time let your new products quickly on the market.

Connector of international brand big factory is expensive

If your purchase volume is very large, but the price of connectors of these first-line factories cannot be reduced, then you can also ask us to develop this product.We can develop products with the same quality as the original factory, or design products more suitable for your use according to your application, thus greatly reducing your overall purchase cost and other potential costs.

You also worry that your new product will soon be copied by competitors in the market

If you are worried, then you may consider developing some new connectors, new connection solutions, we only provide you with the exclusive supply.The unique connection between the client and the host allows you to hold the client firmly.

Having trouble finding the ideal connector

Sometimes a standard solution may not match your needs.Unique applications and equipment require special electrical connectors.The good news is that manufacturers and consumers now have many different types of connectors to choose from, and if you can't find a product that fits your needs, you can use custom connectors.Custom connectors are specially designed and manufactured to meet your specific specifications. You can adjust the characteristics, performance, model and so on of the device.You can make small changes to existing products, or you can create new products.

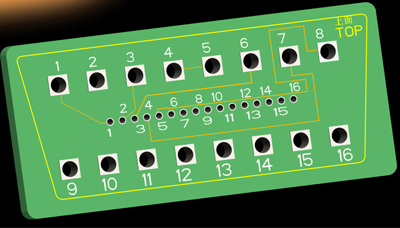

PCB Design & Manufacturing Services

The design of Printed circuit board (PCB) is based on the graph of electric circuit principle, then realize the function the circuit designer need. The design of the printed circuit board mainly refers to the layout design, need to consider various factors such as the layout of the external connections, the layout optimization of the internal electronic components, the layout optimization of metal wire and hole, electromagnetic protection, heat dissipation etc. Good landscape design can save production costs and achieve good circuit performance and heat dissipation performance. Simple layout design can be implemented by hand and complex layout design be achieved with the aid of computer aided design (CAD).

Custom connector drawing service

CAD 2D/Proe 3D drawing service new product design and customization service

CAD 2D drawing service

CAD 2D drawing service is to conduct mapping according to samples provided by customers, provide corresponding 2D view service or provide corresponding 2D engineering drawing service according to specific requirements provided by customers, so as to provide customers with design review and production and processing customization in accordance with 3d 2D engineering drawing.

CAD 2D drawing refers to the projection direction of product shape or section on x,y or x,z or yz plane respectively, and the corresponding length, width and height dimensions are marked out, so as to express a complete product structure standard through three views and sectional drawing.

Proe 3D drawing service

Proe 3D drawing service refers to providing the corresponding 3D view service according to the samples or specific requirements provided by customers. 3D drawing can vividly present customers' ideas and continuously improve according to customers' requirements until customers are satisfied with 3D drawing.For the internal structure of the product, 3D drawing can be viewed and analyzed, so that customers have a complete understanding of the internal structure of the physical appearance.Customized for late production and an intuitive standard.

ProE 3D drawing software is a 3D drawing software with excellent performance, which can provide x,y and z coordinate views and view various sizes.At the same time, 3D view can be converted into CAD 2D view, which greatly saves the time of drawing CAD 2D picture. As soon as 3D picture is completed, 2D picture will come out.It can effectively realize the communication between the product terminal customers and the product production enterprises or departments, and reduce the communication difficulties or differences in the communication.

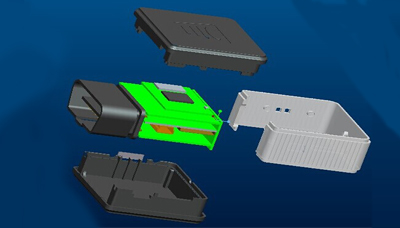

Custom Plastic Enclosures/ Housings

Plastic electronic enclosures, plastic housings, plastic cases, plastic mould designing and manufacturing

JH-C owns a plastic factory engaged in designing and manufacturing plastic electronic enclosures, plastic housings, plastic cases, plastic boxes, plastic mould. We can provide the schematic design of plastic product for our customers. Our rich experienced engineers can design an excellent product structure, product shape for world wide clients. We also provide free sample making, free customized scheme.

Plastic products design process

Determine the requirements of product functional and appearances

Draw a preliminary design

Make Prototype model

Product testing

check and correct the design

Formulate important specification

Open mold to produce

The quality control

Plastic products design principles

Determine the shape, size, appearance, material of the product in accordance with the product function.

Designed products must conform to the principle of molding, mold making is easy, forming and later processing is easy, but need to keep the product function.

Product design checklist, it will help to make sure the design of a variety of factors

General information:

What is the function of the product?

What is the required tolerance?

The consideration of space constraints ?

Define the working life of the product?

Consider product weight?

Have you acknowledged specifications?

Is there a ready similar application ?

Plastic products Structure:

The status of using the load?

The parameter size of working load?

The duration of using the load?

The allowance for deformation?

The environment

What is the using temperature environment?

The using or removing for chemicals or solvent?

What is the environment of temperature?

What is the service life in the using environment?

Plastic product Appearance:

Shape

Color

Surface processing such as texture, spray paint, etc

Economic factors:

What is the forecasted price?

What is the price of the product designed current?

The possibility of reducing costs?

More designs http://connectors-cable.com/en/product-4-1.html

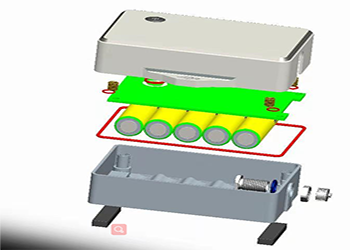

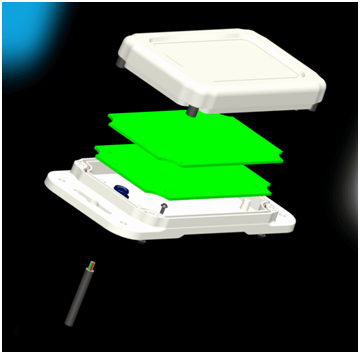

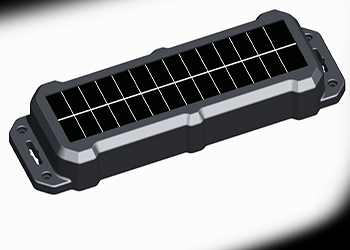

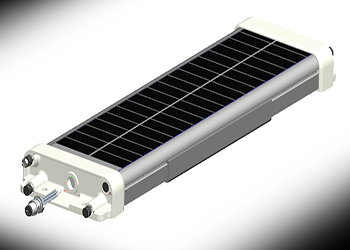

GPS Waterproof Enclosures/ HSG/Box Design

JH-C provides customers with professional waterproof box/shell Design. Before designing water-resistant box and case, you need to figure out the use environment of the product.

1. Indoor use may splash water on the surface

2.Use it outdoors in the rain

3.Use in shallow or deep water environments for long periods of time

We need to determine waterproof level according to these application environments so as to achieve the purpose of use and also save cost. General waterproofing grade is between IP63 to IP68. It is divided into

IP63: there is no effect when water or rain water drops on the housing from 60 degrees corner;

IP64: there is not affect when liquid is splashed to the shell from any direction ;IP65: wash the housing or shell with water without any harm;![]()

IP66: it can be used inside the cabin environment;

IP67: it can be resistant to immerse in a short time (1 minute);

IP68: It can resist water when it is submerged under a certain water pressure for a long time, such as deep-water cable.

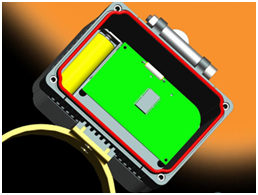

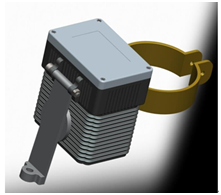

At right picture, a waterproof box is placed outdoor open air, which is equipped with electronic components, circuit boards, batteries, sensors, therefore, its waterproof protection rate needs to achieve IP67.

The bracket design for waterproof box

The waterproof box needs to be fixed on a circular column, we need to design an opening metal locking ring. The locking ring will be used to connect the waterproof case and the column. To make metal locking ring and waterproof box formed a solid connection, our design engineers did some professional design. They made some mutual matching groove design respectively in the waterproof box and the metal ring, and the metal nuts were built into the box body by nut embedded molding process. Therefore, the nuts and the box become one entity and won't not loose. Metal nut is not easy to slip teeth. After the connection between metal ring and case body is good, we can lock the metal ring on the box by screws, so that the screw can mainly withstand horizontal force, the matched groove structures can bear the vertical force.

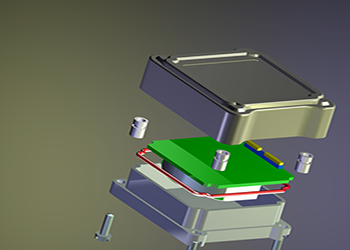

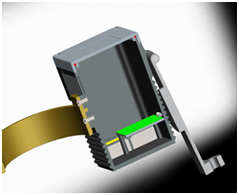

The internal structure design for waterproof box

The internal of the waterproof case needs installing battery, PCB, sensor. Therefore, we need to carry out internal structural design according to the actual size of these components. At the same time, we need to consider the installion position of sensor by our customer re quirements.

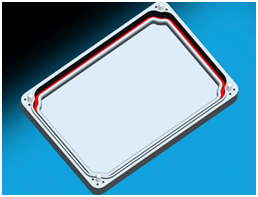

Waterproof cover design

1. What is the fastening method between waterproof cover and box?

Using screws and embedded metal nuts come true the tight connection.

2. Which type of waterproof structure will be chosen?

First, we need to understand common waterproof design methods:

Seam Allowance method, waterproof ring method, ultrasonic method, secondary injection method, sealed and insulated circuit waterpoof design method.

When you design water resistant electronic products, you must make the water level of electronic products clear. Structural design methods are vary with waterproof grades. For example: the secondary injection waterproof design method can achieve IP8, Seam Allowance waterproof design method can only reach IP4.

We choose the combined waterproof design methods of Seam Allowance and waterproof ring. Thus the waterproof box can reach a higher waterproof level.

More classic designs of waterproof structure http://connectors-cable.com/en/product-4-1.html

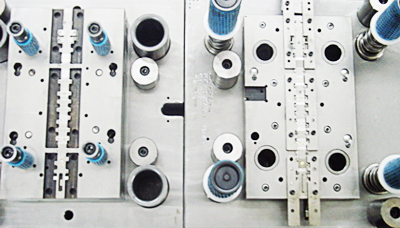

Precision Mould Manufacturing

The company mainly engaged in electronic products, medical products shell, electronic packaging, waterproof casing waterproof outdoor products shell digital products shell, gift case, instruments and meters, electrical products shell, shell, automotive sensors, the constant temperature box shell, remote control box products, injection processing, mold processing, injection mold and plastic mold design and manufacturing, has a complete and scientific quality management system.Integrity, strength and product quality by the industry recognition.Welcome friends from all walks of life to visit, guidance, business negotiations.

Mold department has high-speed CNC machining center, mirror spark machine, low speed linear cutting, quadratic element and other high-precision CNC mold processing and testing equipment.Specific equipment :3 CNC machining centers, 15 milling machines, 3 grinding machines, 6 line cutting machines, 5 spark machines, 1 secondary equipment, more than 30 drilling machines, lathes.The grinding precision of the die processing equipment is 0.002mm, the discharging precision is 0.005mm, and the linear cutting precision is 0.002mm.

2. Since its establishment, the company has been constantly innovating, striving for perfection, doing every detail well and adhering to the basic principles of "integrity, responsibility and enthusiasm".We are committed to using technology to provide customers with better experience and service.We hope that we can make continuous improvement according to the requirements of customers, provide customers with satisfactory products and services, grow together with customers, and achieve a win-win situation!

3. Our company has an independent research and development team, which can guarantee customers' requirements on product and mold design, ensure that new designs and new products are launched every month, and make preparations for customers to constantly explore new markets.At the same time, it can effectively guarantee the competitiveness of our partners in the market.We provide product design and mold design, production, electronic product assembly integration, so that customers from the mold to plastic electronic products one-stop shopping.

4. The price of all products of our company has great advantages on the premise of the same raw materials and product quality, but please remind every customer that we cannot use our price to compare with the products with poor quality and low price.

5, quality assurance: all our mold products, plastic and electronic products are made of materials confirmed in the quotation, such as product material quality problems, we promise to purchase and bear the freight!

6. We provide customers with customized molds, customized plastic products and electronic product shell samples.You only need to provide confirmed drawings or samples, we will strictly in accordance with your requirements for production, to provide you with satisfactory products!

7. Delivery commitment: we promise to perform all production in strict accordance with the production and delivery requirements of the sales contract.If the change of drawings in the production process leads to the change of delivery date, we will arrange a very timely time for the change.At the same time, we need your cooperation to discuss details according to our schedule and reach an agreement on business requirements. Otherwise, it will be difficult for us to reach the original delivery date.

7, Delivery commitment: we commitment to strictly execute all production according to the production delivery requirements of the sales contract. If there is drawing changes in the production process cause the change of the delivery date, we will arrange very top time for changed schedule. At the same time, we need your cooperation to discuss detail information and reach an agreement on business demands by our schedule, or it is difficult for us to achieve the original delivery date.