Product Categories

Contact detail

- Mobile Phone:+86 13662603519

- Tel:+86 755-23063852 13662603519

- Email:master@jh-com.com

Chat Now:

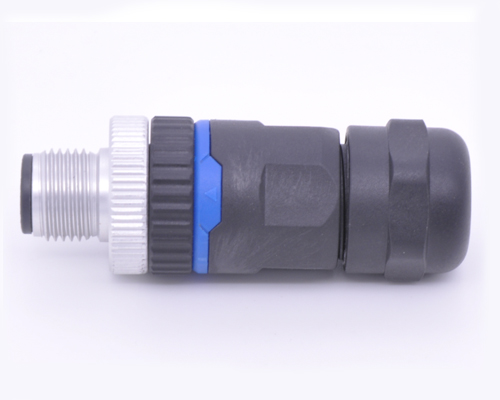

M12 Assembly Connectors WF

M12 connectors/cables should be used in industrial automation technology. Automation systems integrate more and more connected devices, including sensors, brakes, actuators, etc.These devices require a stable and reliable connection to provide power and signal transmission, And need to work in a complex environment, so the need for waterproof, dustproof, corrosion resistance function, M12 connector is in this growing demand is rapidly developed.

M12 connecting line can be divided into welding line and locking terminal type according to the wiring mode;According to the assembly mode, it can be divided into assembly type, type and panel type.

According to the anti-interpolation encoding, it can be divided into A encoding, B encoding, C encoding, D encoding, P encoding, S encoding, T encoding and X encoding.

According to the shape, it can be divided into M12 180-degree straight connection line, M12 90-degree elbow connection line, M12 t-type connection line and M12 y-type connection line.

There are also two types of shielding and non-shielding.There are 3Pin, 4Pin, 5Pin, 8Pin, 12Pin, 17Pin or 3 cores, 4 cores, 5 cores, 8 cores and 12 cores according to the number of needles or cores.

The skin material of the connecting wire is PUR, TPE, PVC, etc.The M12 connecting wires of fulaike are all in conformity with RoHS, CE and UL certification, with excellent quality, affordable price and short delivery time